Cell. Competence Center of Additive Manufacturing based on High Deposition Rate by direct deposition of powder and wire (LMD and WAAM)

DESCRIPTION

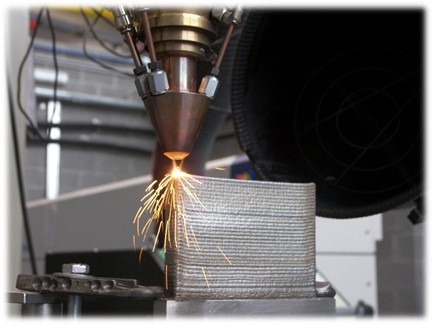

Pilot cell for the application and comprehensive development of metallic additive manufacturing in Directed Energy Deposition technology.

Equipment, resources, software (CAD-CAM), knowledge related to additive manufacturing (LMD and WAAM) are made available for the companies. This also includes the study of the process industrialization and the integration of those processes in the production chain (combination of the total flow of manufacturing from the powder/wire to additive manufacturing process, heat treatments, machining and surface treatments).

It is available:

- 4 robotized cells

- A gantry (7 x 3 metres)

- 2 facilities of 3 axes (possible to include a fourth rotation axis)

-

LMD-powder. These facilities are able to combine with three optics and nozzles for LMD (one of them is capable of controlling the deposition width in real time). It is possible to simultaneously feed with two different materials.

WAAM-wire_with PAW, TIG and CMT technologies (Fronius) with different technologies of deposition path control (equipment continuously updated 2017).

It is provided the possibility of working with reactive materials like titanium (in controlled atmosphere) and with control systems of local atmosphere (with local protection system, in development by Addispace project).

This infrastructure currently presents a series of sensors to the capture of process data (developed in COMBILASER project 2015-2017) and it is possible to establish the required connectivity for ICT platforms. Finally, it is worth noting, the development of a CNC systems of Fagor provided with an accessory to process control (laser) based on optimized parameters database and scalable to any machine with a CNC control of Fagor Automation.

It should be noted that it is also provided a platform of LMD process control with optical and thermographic process sensors):

- to CNC advanced environments

- with LABVIEW platform control

- connectable to platform or IoT infrastructure

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Arc welding processes: PAW, TIG, CMTPAW: Plasma Arc Welding

TIG: Tungsten inert gas welding

CMT: Cold Metal Transfer welding

Different types of heads

ABB robot, robot ASEA IRB 2000, Robots FANUC 1 and FANUC 2

Different types of lasers

Powder feeder of 2 units with heating and able to be remote connected

SERVICES OFFERED BY THE ASSET

Additive manufacturing integration in industrial productive processes. Hybridization of processes.

Bring technology to the companies and related opportunities and risks.

Parts manufacturing by LMD

Smart process controlling and temperature and melt pool size monitoring during LMD process

Surface treatments and repairs of parts manufactured by LMD

Test (materials, characteristics,…) including powders and assess their processability

Test ICT systems related to simulation and CAD-CAM-CA_x in a controlled environment prior to their commercial deployment

Training

ENTITY MANAGING THE ASSET

LORTEK S.C.

Contact person: Emma Gil Murillo

Other related assets

Tell us about your need

Let us get to know you better. If you are looking to implement intelligent technologies and advanced materials that improve the efficiency of your company's production system to offer solutions with more added value, fill in this form.