NAME WAAM Machine for metal components manufacture

WAAM Machine for metal components manufacture Features: - Own CNC specific for additive manufacturing - Max. piece size: 1400x900x500mm aprox. - Max. piece weight: 300Kg - X-Y-Z axis feed: 15-15-2 m/min - Possibility to deposit on both sides - Capacity of plasma, CMT® and TopTIG® generators integration - Fairing with inert gas atmosphere: designed to work with highly oxidisable parts - Interface that facilitates the machine use - WAAM CAD/CAM system - In-process monitoring system - Traceability system. Part manufacturing report.

FIELDS OF APPLICATION

AM Digital Chain.

AM process validation

AM/3D Printing Process

Design for AM and Digital pre-processing

Post process

Supporting technologies and processes

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

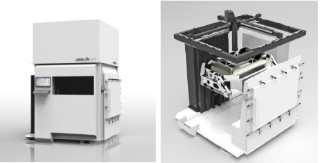

Addilan Machinne v1.0

-

Equipo MIG Kemparc Pulse 450

-

Laser scanner with light compensation

-

Plasma Tetrix 400 confort

-

Termographic camera

SERVICES OFFERED BY THE ASSET

Feasibility analysis of part manufacture using this technology

Part manufacturing optimization using additive manufacturing. Development of trajectories and manufacture of demonstrator.

Manufacturing of several geometries using WAAM

Parameter optimization, tool path and simulation programming, whole 3D part or specific geometries manufacturing and part measurements.

Model development for additive manufacturing

Development of models that relate the characteristics of the deposited material (geometry) with the monitored process parameters for the development of control rules

Piece design support

Support the redesign of the parts that will be manufactured by WAAM (plasma and MIG)

Training

Technical training in WAAM process (theoretical-practical, WAAM, MIG).

Validation and advice of new products for additive manufacturing

Integration, evaluation and advice in the improvement of new equipment, sensors and accessories for additive manufacturing by WAAM (3D measurement scanners, filling torches, postprocessors, simulation tools, etc.).

ENTITY MANAGING THE ASSET

Contact person:

Alfredo Suarez

alfredo.suarez@tecnalia.com