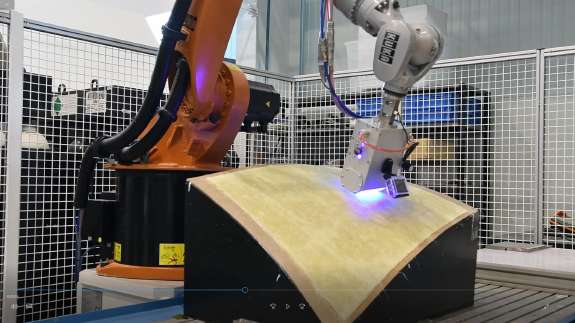

UV curing composites manufacturing reseaarch cell

DESCRIPTION

Automated cell manufacturing fiberglass composites starting from coils of all types of fiberglass fabrics, MAT, Combi and woven, based on ultraviolet (UV) curing technology. The cell consists of a prototype of manufacturing of preimpregnated UV, which has different processes, such as impregnation, dosing and precurado, and a second prototype of compaction and curing of the final composite, consisting of a compactor head driven by a robot. The cell is completed with the necessary equipment for the monitoring of the process, being able to measure forces, temperatures and degree of curing by means of the measurement of the dielectric properties of the material (DEA analysis). This cell also contemplates the characterization of the final composites by measuring porosity by ultrasound, thickness and fiber content by pyrolysis.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

DEA analysis equipment. Epsilon 288 from NETZSCHThis equipment is capable of making measurements of the dielectric properties of a liquid material while curing occurs. The evolution of these dielectric properties allows us to monitorize the degree of curing in the process, critical parameter in the productive processes of polymeric composites.

UT inspection tools: single-element transducers and Phased Array transducers, Olympus Focus PX acquisition system.

Ovenfor analysis of fiber content by pyrolysis

Prototype consisting of a head actuated by a robot. With this prototype the consolidation stage of the final composite is studied by applying UV light and pressure simultaneously.

The processes of manufacturing prepreps with UV resins is researched in this prototipe. The process is composed by three stages, impregnation, dosage and precuring.

SERVICES OFFERED BY THE ASSET

Characterization of porosity, thickness and fiber content

Complete development of composite piece manufacturing using a new process based on UV technology.

Degree of curing monitoring by DEA

ENTITY MANAGING THE ASSET

IDEKO S.C.

Contact person: Javier Vallejo

Other related assets

Tell us about your need

Let us get to know you better. If you are looking to implement intelligent technologies and advanced materials that improve the efficiency of your company's production system to offer solutions with more added value, fill in this form.