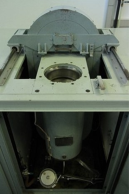

NAME Hot Isostatic Press (HIP)

The asset is a HIP unit model ASEA QIH-6 able to reach pressures as high as 2000 bars and temperatures up to 2000 °C with a graphite heating element and 1450 °C with a Mo heating element (both available). The working volume is a cylinder with 110 mm in diameter and 240 mm high. Workload can reach 30 kg and the standard atmosphere is Ar although the graphite-heating element also accepts nitrogen. The working area is in the interior of a wire reinforced pre-stressed vessel. The vessel has been designed according to Fracture Mechanics criteria to guarantee leak before cracking. The axial stresses are supported by a wire reinforced frame. The asset is very flexible in the design of the temperature and pressure cycles. HIP is mainly use for healing defects (pores, cracks, segregations, directionality in properties) but also as heat treatment simplifying the production sequence.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

ASEA QIH6 HIP unit

-

Connection to the internal network

SERVICES OFFERED BY THE ASSET

HIP to improve the properties of components produced by AM

HIP is present in the AM value chain as a post-process (as a next step to the 3D printing). The main function is the improvement of the mechanical behavior of the parts healing defects (pores, cracks do not connected with the surface of the parts, segregation, columnar structure …). The improvement in properties are also associated to a decrease in the deviation obtained as well the residual stresses. It also allows (depending of the cooling capacity) the reduction of the process steps simplifying heat treatments.

Process parameters optimization

Determination of the optimum HIP parameters in order to improve the mechanical behaviour. This service includes tests at different Pressures, temperatures, times, chemical composition, mechanical and microstructural characterization.

Production of prototypes and demonstrators

Post-processing in AM: HIPping of AM prototypes and demonstrators

Technical feasibility studies.

Validate the technical and economic feasibility of the production of parts by AM+HIP

ENTITY MANAGING THE ASSET

Contact person:

Iñigo Iturriza Zubillaga

iiturriza@ceit.es