Center for Development of Additive Technologies for Plastics and Composites

DESCRIPTION

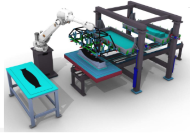

The Centre has the capability to develop or reformulate new binders and thermoplastic resins a) suitable for processing by means of additive technologies such as FDM (filament or direct extrusion) and Laser sintering or b) to meet new requirements (mechanical, fire resistance, electrical, etc.).), new additive processes for the pre-forming of composites with continuous fiber, post-processes to improve surface and mechanical properties, design of moulds and tools, integrate electrical functions in non-metallic components and develop new equipment and control software.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Additive Manufacturing Unit: Stratasys uPrint SE 3D Printer, TUMAKER Printer, ZORTRAX M200 Printer, EOS - SLS PrinterSERVICES OFFERED BY THE ASSET

Materials development

Post-process development

Process development

Product development

ENTITY MANAGING THE ASSET

FUNDACIÓN TECNALIA RESEARCH & INNOVATION

Contact person: Alfredo Suarez

Other related assets

Tell us about your need

Let us get to know you better. If you are looking to implement intelligent technologies and advanced materials that improve the efficiency of your company's production system to offer solutions with more added value, fill in this form.