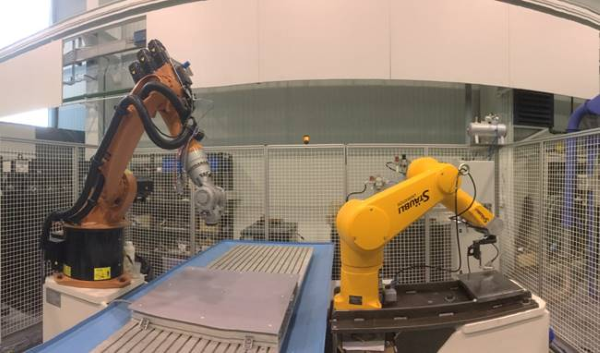

NAME Cell for research on manufacturing and inspection of metal and composite parts

Cell for research on robotic systems for manufacturing and inspection of metal and composite parts. it has three medium size industrial robots and specific tools to perform manufacturing operations, such as finishing of metal parts (grinding, polishing, deburring), manufacturing of composite parts and non-destructive testing by ultrasonics and eddy currents. It is a fenced space for operator safety, with a 3 meter long aluminum table for the mounting of parts and a lower tray to collect liquids used during inspection. It integrates a dust and chip suction system, and electric and pneumatic source to feed the tools. The necessary software for cell programming is available. It integrates a cloud based monitoring and analytics system, and a real time process controller programmable in Matlab, Simulink and Codesys.

FIELDS OF APPLICATION

Advanced manipulation with robots

Manufacture and assembly of components by robots

Quality control with robots

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Kuka KR16 Industrial robots

Kuka KR16 industrial robots (2 units, nominal load 16 kg, with the possibility of synchronizing movements between them with Kuka RoboTeam)

-

Monitoring and analysis in the cloud

Monitoring and analysis in the cloud with OPC DA/UA, MT Connect, Modbus TCP, Profinet, Profibus, I/O-Link, SQL, ODBC, XML, Rest API, MQTT and programmable real-time process controller in Matlab, Simulink and Codesys.

-

Sensors for process monitoring

Sensors for process monitoring: force, vibration, position, thermography, dimensional artificial vision, surface roughness, etc.

-

Stäubli TX90L industrial robot

Stäubli TX90L industrial robot (1 unit, nominal load 6 kg, maximum 15 kg) Stäubli SRS, Kuka WorkVisual, CAD/CAM Delcam Autodesk PowerMill Robot programming software

-

UT inspection and manufacturing tools

UT inspection tools: mono-element transducers and Phased Array transducers, Olympus Focus PX acquisition system. Induced currents, Olympus Omniscan NX acquisition systems.Tool for manufacturing metal parts by abrasion, radial flexibility, pneumatic force control and pneumatic motor.

SERVICES OFFERED BY THE ASSET

Investigación en fabricación de composites

Estudio de viabilidad, ensayos y análisis de resultados en diferentes fases del proceso de fabricación de piezas de composites: deposición de fibra, curado, manipulación de pieza.

Investigation in defect inspection through non-destructive testing

Feasibility study, tests and analysis of results in non-destructive inspection with ultrasound, induced currents and active thermography in metal parts and composites.

Investigation in the superficial finishing of metallic pieces

Feasibility study, testing and analysis of results in the sanding, polishing, deburring and grinding of metal parts

Research in communications and connectivity with robots

Feasibility study, tests and results analysis for the development of communications with robots, between robots, and between robots and other machines.

Research in industrial robot control techniques

Feasibility study, tests and results analysis for the development of communications with robots, between robots, and between robots and other machines.

Research in the robotization of manual manufacturing operations

Feasibility study, testing and analysis of results in the development of robotic systems replacing people in manual operations

ENTITY MANAGING THE ASSET

Contact person:

Asier Barrios

abarrios@ideko.es