NAME Cell for research on high precision parts

Cell for research and development of high precision grinding processes in small dimension parts from industrial sectors with high dimensional and surface quality requirements, in sectors such as automotive, optics, medicine, energy, aeronautics and aerospace. The cell is composed by an horizontal cylindrical grinding machine equipped with a double rotating head, with the possibility of incorporating conventional and superabrasive wheels, which work at high cutting speed. The versatility of the machine allows to perform processes of plongeé, grinding of faces, and peel grinding. A second equipment of the cell is a cylindrical grinding machine for grinding external, internal diamters and face grinding, with high precision and stability. The cell is completed with a centerless grinding machine of high grinding capacity that allows work in plongeé and throughfeed, for an extensive variety of parts geometries. The three machines, connected to each other, can work independently or in combination, having a specific software interface (HMI), which allows intuitive and simple programming of the different cycles mentioned above, in addition to special cycles such as grinding of shapes (cams, eccentric). The cell is completely monitored for the measurement of vibrations, forces, temperatures, in addition to the working parameters. This monitoring is transferred to the cloud platform from which the monitoring parameters are processed and analyzed, and is complemented by simulation models of the behavior of the three units that compose it. The cell also has systems for non-destructive inspection (NDT) through ultrasonic, eddy current and active thermography. It has the ability to design specific sensors for applications and parts of interest, so that in addition to standard verification of the results of the processes studied and the rectified parts, customized solutions can be developed and tested. The three units are connected to each other in addition to connecting to IDE.004 assets.

FIELDS OF APPLICATION

Grinding and finishing technologies

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Danobat Estarta 650 centerless grinding machine

Centerless grinding machine for working in plongeé and throughfeed conditions, for an extensive variety of geometries of pieces.

-

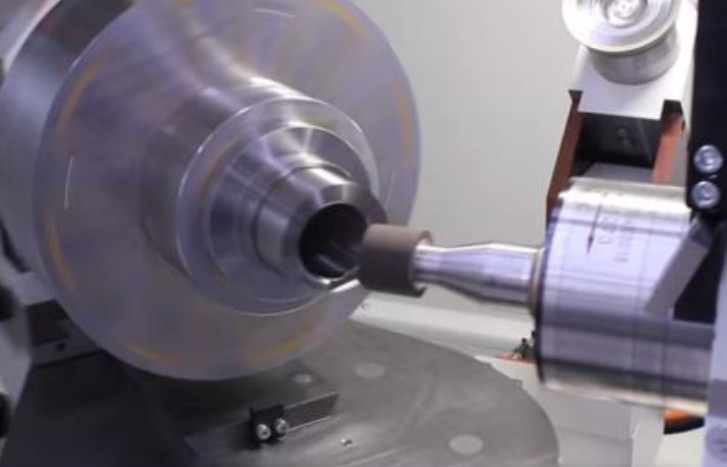

DANOBAT LG 1200 cylindrical grinding machine

Horizontal cylindrical grinding machine equipped with a double grinding wheel rotating head, with the possibility of incorporating conventional and superabrasive grinding wheels. The versatility of the machine allows to perform processes such as plongeé, grinding of faces, and peel grinding.

-

Danobat Overbeck IRD grinding machine

cylindrical grinding machine for high precision grinding OD, ID and faces, with high precision and stability

-

Non Destructive Testing

Equipment for verification of surface integrity, thermal damage and residual stresses through Ultrasound, Eddy Current and Active Thermography

-

V3 proprietary algorithms for optimising grinding cycles

Special programming algorithms that allow optimising the total grinding cycle by optimising the key parameters: precision, cycle time, energy consumption.

SERVICES OFFERED BY THE ASSET

Research on new grinding processes and special grinding cycles

Design and testing of new special grinding cycles for parts of high value and complexity: new materials, process conditions, lubrication. Testing of special grinding cycles: non round shapes, curvics, thread elimination, smooth cycles, hard materials, ceramics

Research on the behavior of new advanced components: grinding wheels, cooling systems, measurement systems, special heads, dressing systems

Testing, evaluation and validation of components of grinding machines: new wheel compositions (superabrasive, carbon fiber bodies, conventional high speed wheels), cooling systems and elements, machine-integrated measurement and inspection systems, dressing systems.

Tests on special production conditions for particular parts

Definition and design of new cycles that provide productive advantages to parts of special complexity

Training and updating of specialists

Specialized training courses for new professionals and for updating professionals to new technologies.

ENTITY MANAGING THE ASSET

Contact person:

RAFA LIZARRALDE

rlizarralde@ideko.es